SDS Multistage Split Case Pump

SDS Multistage Split Case Pump Description

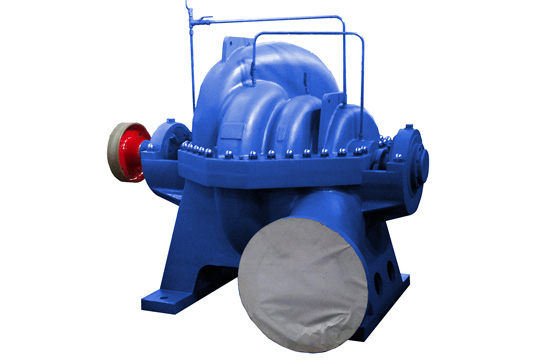

SDS type of seawater desalinization pump is our new de- signing energy-saving type multistage high pressure centrifugal pump with split casing. It is based on worldwide advanced hydraulic model, adopted both CFD (Computational Fluid Dynamics)and FEA (Finite Element Analysis). This type of pump is specialized in desalinization of sea water with the advantages of high efficiency, good performance of anti-cavitations, smooth operation, and easy maintenance. It is mainly used for pressing seawater and delivering the fluid with few solid particles.

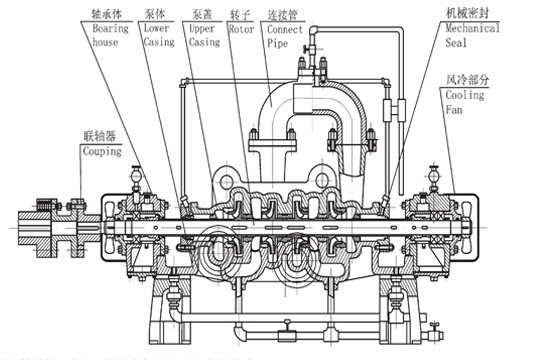

SDS desalinate pump adopt the self-balance mechanical structure

The delivery chambers are uniform distribution to balance the radial force. Impellers are symmetrically or back-to-back arranged to balance axial thrust. Thickening the shaft by optimize calculating machine and experimental verification. The key of impellers are symmetrically arranged to balance part of the radial deflection. Strictly dynamic balance is adopted on rotor parts to remove the unbalanced mass and adopted elastic couplings to balance the radial force.

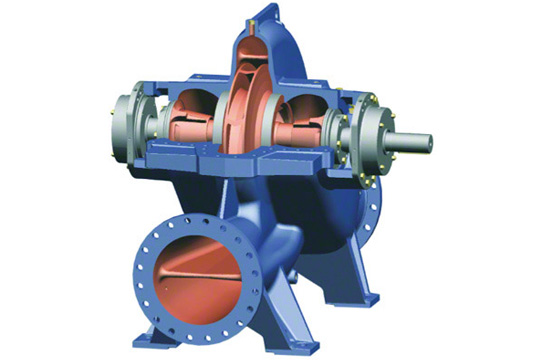

SDS desalinate pump of compact structure

The main components are casing, impeller, shaft, shaft sleeve, wear ring, bearing seat, coupling, and etc. It has compact and reasonable structure, occupy less space by reducing the un-necessary balance device.

SDS desalinate pump is designed for pressuring and transporting the seawater

Hydraulic model is specialized designing for seawater desalination pump with smoothing performance. High performance range suits for pump’s service condition.; SDS type desalination pump is designing for seawater pressure and delivering; To adapt the best material to press and deliver seawater which guarantee corrosion resistance and pressure resistance; Special designing of bearing lubrication and cooling to suit for different application;The sealing structure between suction chamber and discharge chamber which reduce leakage, reduce maintenance time and improve delivery efficiency; Low pressure zone is near mechanical seal with flushing pipe water to guarantee good performance and better service life of mechanical seal.

SDS desalinate pump is easy to maintenance

The casing is consisting of upper casing and lower casing. The inlet and outlet are located on each sides of the casing. Ax-is vertical with the shaft, It is very easy maintenance for the SDS type pump because of the structure. It only needs to open upper casing instead of disassembling motor and pipe.

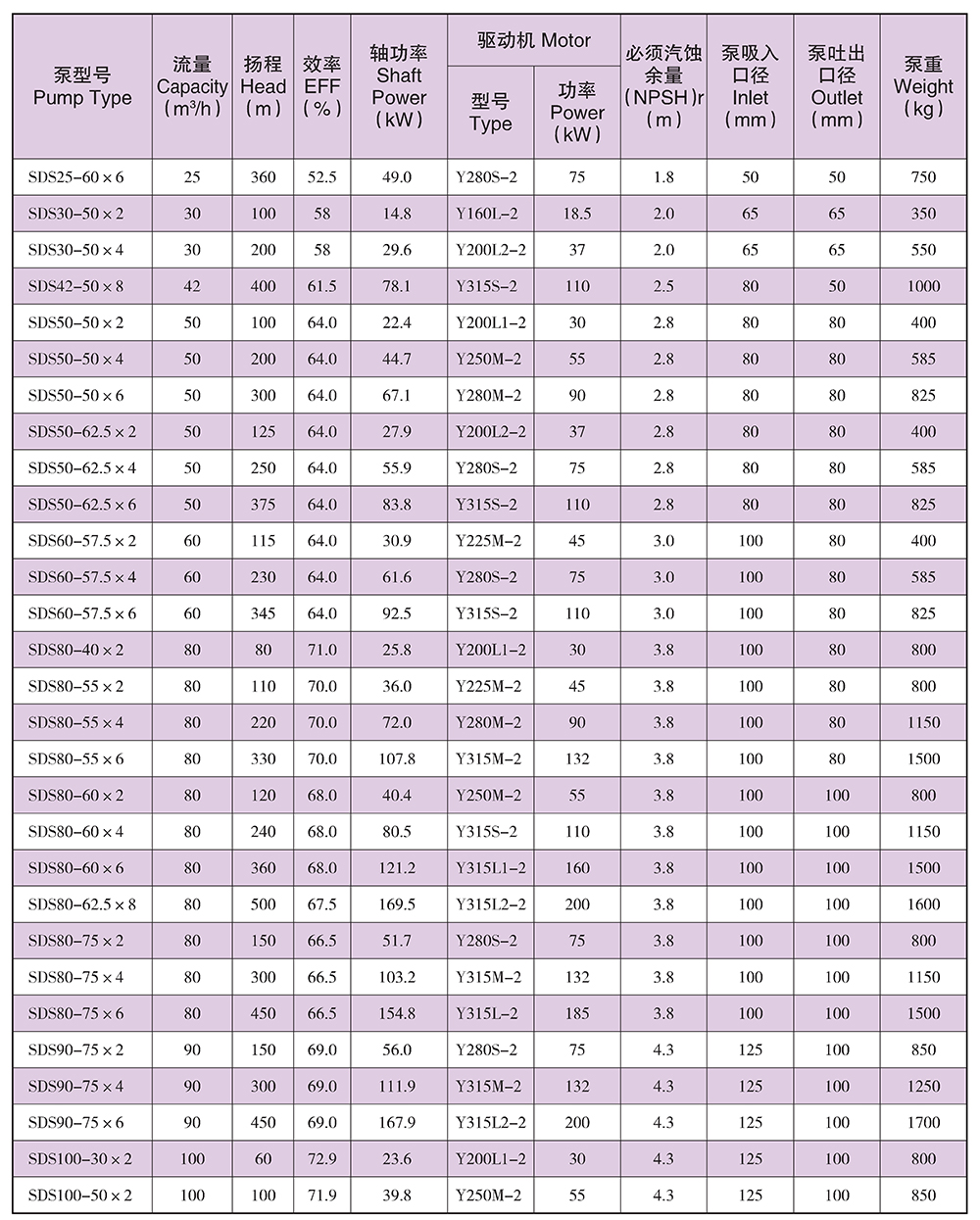

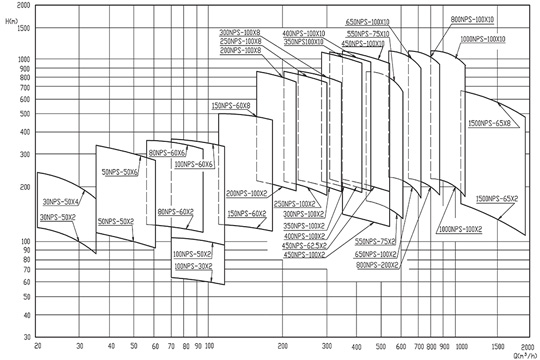

SDS Multistage Split Case Pump Technical Data