Vertical Turbine Pump

Vertical single stage or multistage pump with mixed or axial flow impeller design, broad hydraulic coverage provides best selection to meet specific operating conditions. Fabricated or cast iron, surface or underground discharge head, shaft and bearing combinations promote long life with options of open or enclose line shaft construction. It can be driven by VHS NEMA Standard motor, VSS motor or diesel engine through right angle gear box.

Vertical turbine pumps (VTPs) are a type of rotodynamic pump that use radial or modified radial flow impellers in a vertical configuration. VTPs are typically multistage pumps with several levels of impellers encased in a bowl assembly, and can further be classified as deep well or short set pumps.

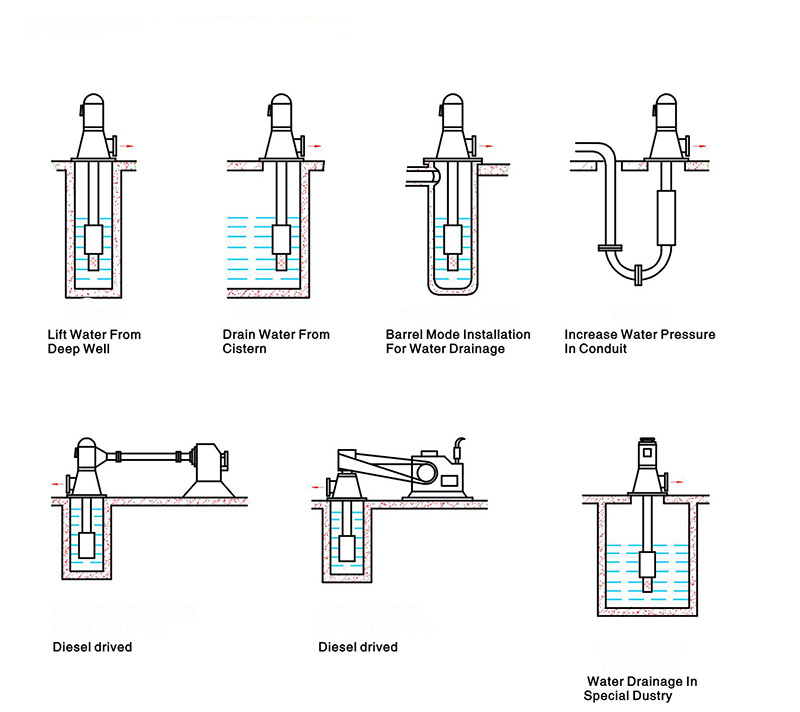

A deep well turbine is usually installed in a drilled well with the first stage impeller laying below the water level of the pump. These pumps are self-priming, typically a multistage assembly, and are primarily used to transport water. The multistage assembly of a deep well turbine pump can be seen in Image 1. Transporting water from deep wells to the surface is the primary application of these pumps.

These pumps transport water to treatment plants, irrigation sprinklers and to faucets in homes. Short set pumps operate very similarly to deep well pumps. Short set pumps will often operate in water pits and typically have a maximum length of 40 feet.

Additionally VTPs can be installed in a suction barrel or can that is installed below ground level to provide additional suction head to the first stage impeller. These pumps operate typically as booster pumps or other applications where low net positive suction head (NPSH) is available.

Another unique application of a VTP is that the pump can be run in reverse and be used as a hydraulic turbine to generate power. When used in this application, the suction nozzle becomes the outlet of the turbine and the discharge nozzle becomes the inlet of the turbine. The efficiency of the pump as a turbine is comparable to the efficiency of the pump. Caution must be used, so please check with the manufacturer prior to using a pump as a turbine.

Application of Vertical Turbine Pump

| Municipal | Waster Plants | Commercial/Industrial |

| Golf Courses/Turf Irrigation | Agricultural Irrigation | Dewatering |

| Mining | Cooling Tower | Water Parks |

| Snowing | Flood Control | River/Sea Water Circulation |

| Fire-Fighting | etc |

Vertical Turbine Pump Material

Bronze, Cast Iron, Carbon Steel.

Stainless Steels – 304,316,316L.

Duplex – 2205

Super Duplex – 2507

Vertical Turbine Pump Installation